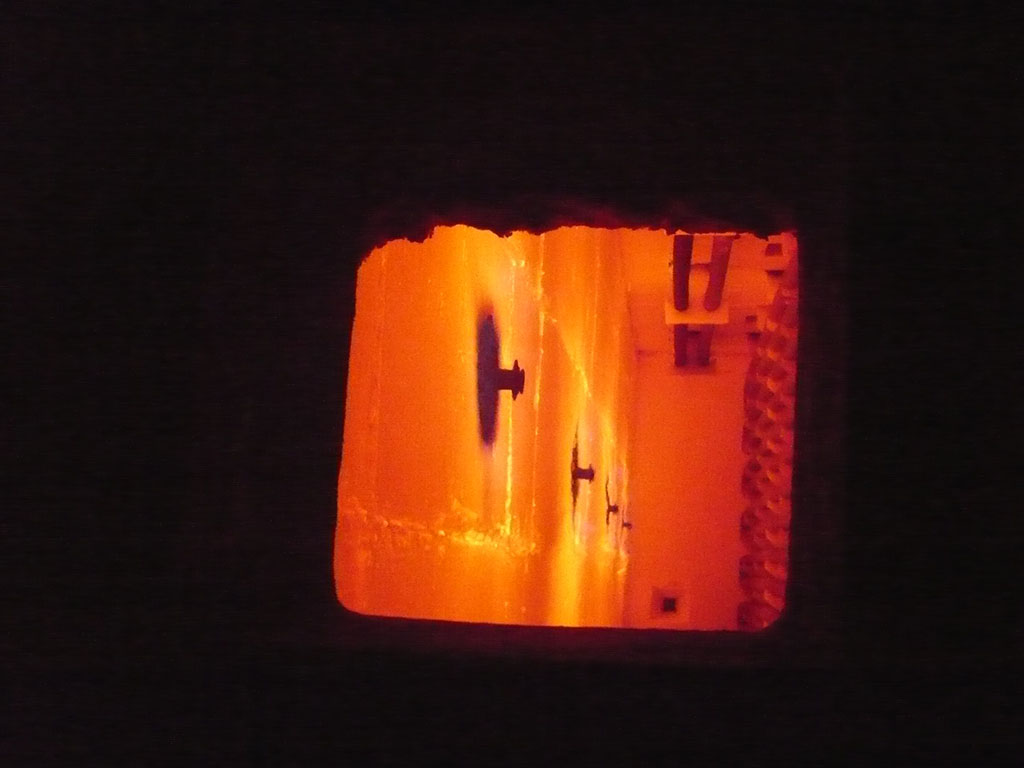

Engineering of Refractory Linings

ALITER-AXI provides various engineering services in the field of refractory technologies

The engineers working in our company will help you to:

- choose the most efficient design for your thermal equipment lining;

- choose materials for lining layers according to their technical characteristics;

- choose thickness of the layers and calculate the vessel surface temperature according to your requirements.

The lining will comply with the equipment operating conditions. All impacts of the operating environment, including thermal, abrasive, chemical impacts, etc., will be taken into account.

Specialists of the Design Department will accomplish a design of lining for your equipment relying on 30-year experience of work in the field of industrial equipment design.

Design documentation is created with the help of the newest 2D and 3D modeling programs and technologies. If it is necessary, our specialists conduct industrial safety assessments and prepare permit documentation.

Engineers of the Refractory Department provide qualified assistance in selection of Russian analogues of foreign refractories. In most cases it is enough to specify the brand name of the foreign castable, analogue of which interests the Customer.

Our engineers will assess the state of your thermal equipment lining on site. After the examination they will issue an official report on the state of the lining, recommendations for further actions and possible solutions to the current problems.

Our specialists can hold training workshops and lectures on the use of refractories and proper operation of your equipment lining.

Our company provides a full range of engineering and consulting services on preparation, installation, maintenance and repair of thermal equipment linings, gives advice on proper operation to guarantee long service of the equipment. We can recommend professional mounting contractors that will carry out construction and installation works on site.