Brochure

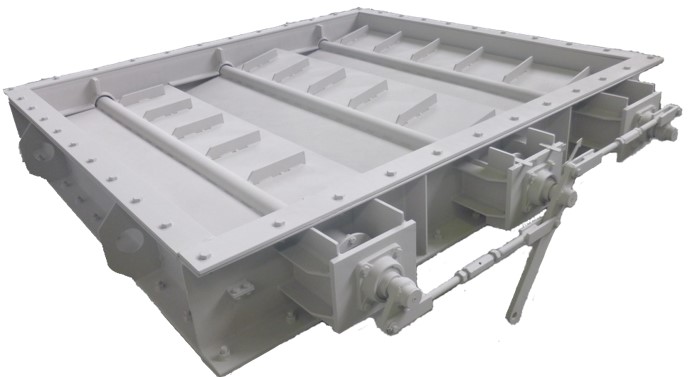

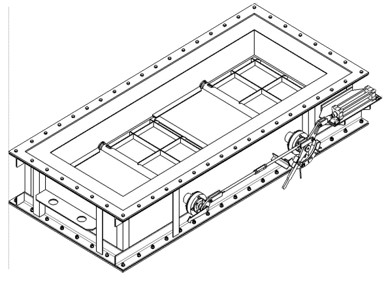

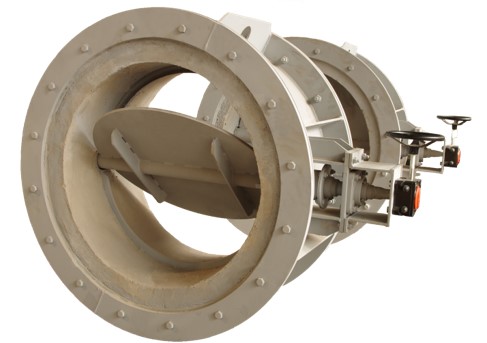

Another area of ALITER-AXI’s activity is the design and fabrication of dampers according to the Customer’s requirements. These dampers are used in industrial air ducts and stacks of fired heaters, boilers, furnaces, etc.

Dampers are widely used in all industries in order to cut off and regulate the flow of operating fluid.

Dampers, manufactured by our company, may be used at operating temperatures from -60°С to +900°С, which allows using them in oil refining, metallurgy, mining, heat power industries.

The type of sealing between blades and body, used in our dampers, is “metal to metal”. Tightness of this sealing is 95-98%.

Our dampers serve to control flow rate of various gaseous fluids:

- Flue gas;

- Air;

- Gas-dust flows;

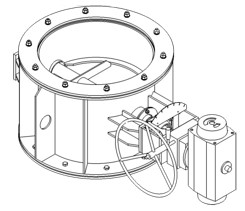

At the Customer’s request a damper can be additionally equipped with an actuator:

- electric;

- pneumatic-electric;

- manual (reduction gear);

The actuator is chosen according to the requirements of the operating services and the parameters of the production area, where this damper will be used.

A damper, fabricated by our company, in a set with an actuator, is a complete module. In order to start operation one only needs to supply power and control signal to the actuator.

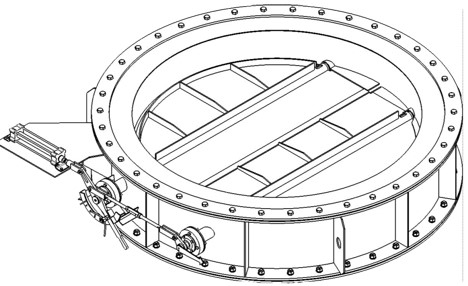

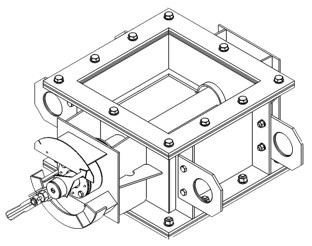

The range of internal dimensions of our dampers’ bodies are from Ø300mm to Ø3000mm for round section gas ducts, and from 300х300mm to 4500х6000mm for rectangular section gas ducts. We can also consider manufacture of dampers with other dimensions.

Depending on the damper operating conditions, the following materials can be used for manufacturing:

Depending on the damper operating conditions, the following materials can be used for manufacturing:

- Ст3;

- 09Г2С;

- Steel 20;

- 15Х5М;

- 08(12)Х18Н10Т;

- 20Х23Н18;

- Other materials approved by the customer

Depending on the size of the gas duct, dampers may be fabricated both single-blade or multiblade. Also, dampers may be lined or not lined inside.

Depending on the properties of operating fluid, dampers may be lined with both light-weight, insulating castables, and denser, abrasion-resistant castables of our own manufacture.

All our dampers are manufactured in our own workshop, located in Saint-Petersburg, Russia.

High-temperature bearings, requiring no maintenance during the whole period of the damper’s service life, are used in ALITER-AXI’s dampers.

If you want to order a damper, please, follow the link in the heading of this page and fill in the Data Sheet.