Dry-out of Industrial Equipment Linings

ALITER-AXI is the largest Russian company specializing in designing, manufacturing and supplying of various high temperature equipment, including furnaces, fired heaters, combustion chambers, internal parts and elements of reactors and regenerators of catalytic cracking and dehydrogenation units, etc., for the needs of oil producing, oil refining, petrochemical and chemical enterprises.

Another activity area of our company is dry-out of linings of process equipment and items in compliance with drying conditions specified by the designer of the lining.

Today ALITER-AXI is a high-profile, cutting-edge and dynamically developing company which employs more than 400 people.

Among our customers are the leading Russian and CIS oil & gas companies, such as Rosneft, Gazprom, Gazprom Neft, Lukoil, Tatneft, SIBUR, KazMunayGas (Pavlodar Oil Chemistry Refinery and Atyrau Oil Refinery, Kazakhstan), etc.

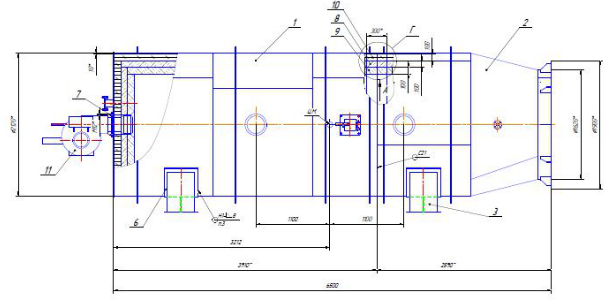

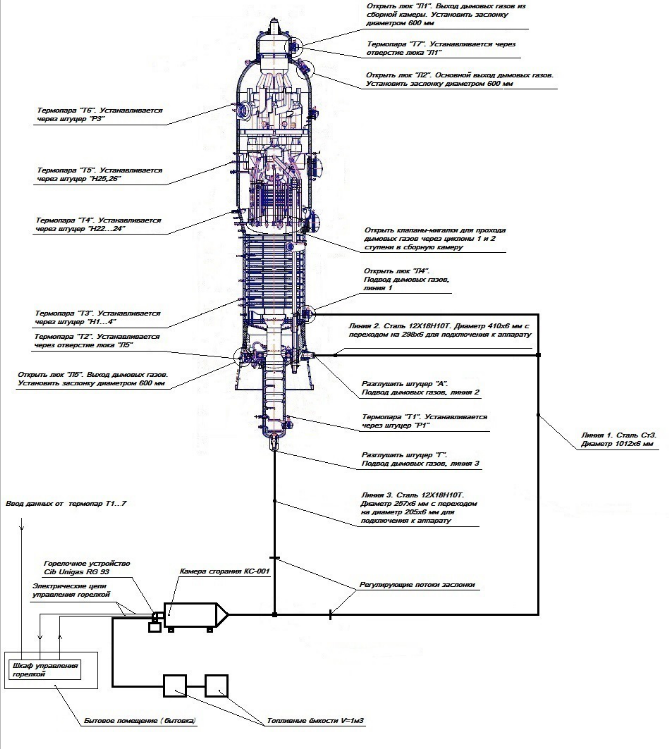

1. Preliminary overall planning of works on the lining dry-out and selection of main and secondary equipment: selection of a burner capable of releasing the required amount of heat to dry the whole lining in accordance with the temperature rise schedule; preliminary design of the combustion chamber; development of basic schemes of the lining dry-out, etc.

2. On-site visit by our specialists for the purpose of exploring the working area, planning the equipment placement, taking the necessary measurements, etc.

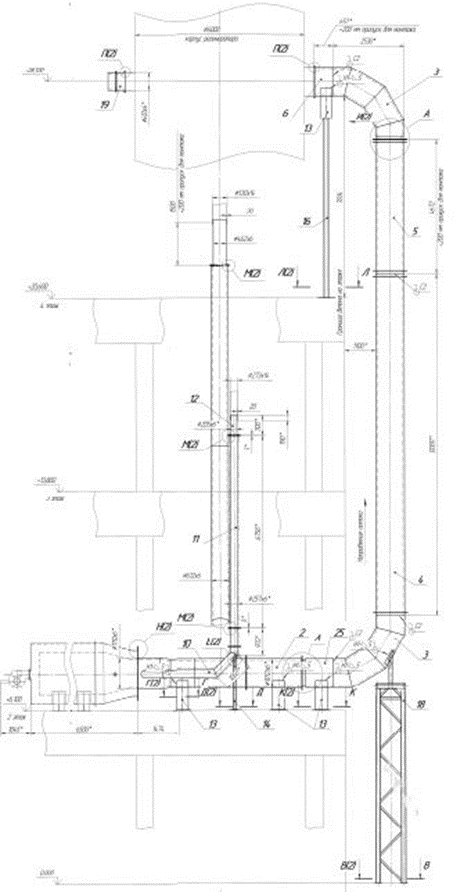

3. Preliminary design of the feeding gas ducts based on the site examination results.

4. Preparation of detailed design documentation for manufacturing of the combustion chamber and gas ducts, which also includes assembly drawings for the combustion chamber installation and gas duct system assembling on the site of lining dry-out.

5. Manufacturing, purchasing, packaging of main and auxiliary equipment.

6. Preparation of an instruction manual listing the necessary equipment and indicating its operating principle; describing the process of lining dry-out, including temperature rise schedule and all the necessary diagrams and drawings.

7. Final packaging of the main and auxiliary equipment, materials and instruments necessary for the works.

Shipment to the worksite.

8. Secondment of our specialists on site and carrying out lining dry-out works.

9. Execution of as-built documentation (final temperature rising and holding schedules, visual inspection certificates, etc.), and acceptance of the works by the Customer.

ALITER-AXI performs works on dry-out of linings of process equipment and items, used by oil producing, oil refining, petrochemical and chemical enterprises, with holding temperatures up to 600 °С.

We are able to perform lining dry-out both at our plant and on site / process unit with the delivery of all the necessary equipment and secondment of specialists for execution of works.

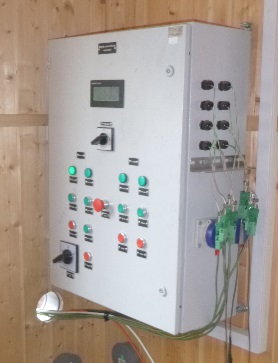

ALITER-AXI Chemical Engineering Plant possesses equipment necessary for lining dry-out, including burners and combustion chambers. The process includes manufacturing and installation of exhaust ducts, arrangement of enclosures for dry-out of external linings or simultaneous dry-out of several items.

| Год реализации | Наименование заказчика | Вид работ |

|---|---|---|

| 2010 | Stavrolen | Full repair of Furnace F-1007 (including dry-out of benzole reactors R9101, R9102) |

| 2011 | Soyuzteplostroi — Peterburg | Preparation of technical documentation for manifolds linings dry-out (Cherepovetsky Azot) |

| 2011 | Gazpromneft Moscow Refinery | Erection of Heater Н-101 of Isomerization Unit (including dry-out of Heater Н-101) |

| 2012 | Promfinstroy | Primary dry-out and steaming out of the coils of Heaters Н-01, 02, 03 of Moscow Refinery’s Catalytic Gasoline Hydrotreater. |

| 2013 | Junix | Dry-out of Reformer Heaters Н-301, Н-302, Н-405 for Novokuybyshevsk Refinery. |

| 2014 | KINEF | Manufacturing and supply of the outlet manifold of Hydrogen Reformer Furnace of Kirishi Refinery (including manifold dry-out) |

| 2014 | Trust Koksokhimmontazh | Set of works on primary dry-out of lining of Heaters 80-П-1 of Vacuum Distillation Unit VT-2 and Catalytic Gasoline Hydrotreater Heaters 32-Н7001, 32-Н7002, 33-Н7003, 32-Н7004 (LUKOIL- Nizhegorodnefteorgsintez) |

| 2015 | Acron | Dry-out of linings of Secondary Reformer Reactor and Waste Heat Boiler of “Ammonia-4” shop |

| 2016 | Pavlodar Oil Chemistry Refinery | Replacement of lining of FCCU Г-43-107 section 200 for Pavlodar Oil Chemistry Refinery, including once-through reactor dry-out. |

| 2016 | Gazpromneft Moscow Refinery | Lining dry-out of: reactor Р-201 upper head; external cyclones Е-201/1,2,3,4; gas ducts from the regenerator to the external cyclone system and from the external cyclone system to the pressure relief device of FCCU Г-43-107 |

| 2016 | Nizhnekamskneftekhim Isoprene Monomer Plant | Dry-out of lining of Isobutane Dehydrogenation Unit external reactors Р-205/1, 2Р-205/2 and regenerators Р-214/1, 2Р-214/2 |

| 2016-2017 | Soyuzteplostroi — Peterburg | Dry-out of lining of Secondary Reformer Reactor 1-Р-1201 with connecting gas duct (PhosAgro Cherepovets) in three stages (separate dry-out of each layer of the three-layered lining) |

| 2016-2017 | Gazpromneft Moscow Refinery | Dry-out of lined panels of Heaters П-1/2; П-1/3; П-3 of Unit AVT-6 (CDU/VDU) |